Global Trade and Supply Chains shape how companies price, manufacture, and deliver products to customers every day. In an era shaped by evolving global trade trends, organizations are learning to balance cost, speed, and risk across complex supplier networks. Understanding supply chain resilience helps firms protect margins when disruptions strike, whether from bottlenecks at ports or shifts in demand. By tracking logistics disruption, tariff and trade policy changes, and the impact on shipping costs and freight rates, businesses can model wallet impacts and optimize spend. This article outlines practical steps to improve visibility, diversify sourcing, and align procurement with demand forecasts to sustain competitiveness.

From the vantage point of international commerce networks, the flow of goods across borders hinges on how firms coordinate sourcing, production, and distribution. Global value chains depend on visibility across suppliers, carriers, and warehouses, and on adaptive responses to policy shifts and currency swings. Strategies like nearshoring, diversification of vendors, and smarter transportation planning strengthen resilience in cross-border logistics. As these logistics networks evolve, data-driven decision making, digital twins, and scenario planning help organizations forecast costs and service levels.

Global Trade and Supply Chains: Navigating Global Trade Trends to Protect Margins

Global Trade and Supply Chains are continually shaped by global trade trends that push firms toward supplier diversification, regional production, and greater digital visibility across the value chain. These shifts influence lead times, input costs, and pricing power, making wallet impacts broader than a single line item. As companies monitor international policy changes and currency movements, they gain a clearer view of how risk is distributed across procurement, manufacturing, and delivery—and how to defend margins against volatility. In this environment, resilience becomes a strategic advantage, helping businesses weather disruptions without sacrificing service levels.

A closer look at global trade trends reveals the dynamic balance between cost efficiency and risk reduction. Diversification of suppliers can lower the probability of a single disruption cascading through the network, but it also introduces greater logistics complexity and potential increments in unit costs. The wallet impact then hinges on managing these trade-offs—optimizing landed costs, visibility, and supplier performance—to shield profitability while maintaining competitive pricing.

Global Trade and Supply Chains: Strategic Responses to Costs, Tariffs, and Disruptions

To translate awareness of wallet impact into action, organizations must strengthen supply chain resilience as a core margin strategy. This includes geographically distributed networks, redundant suppliers, and real-time visibility that enable rapid responses to shortages or demand spikes. While resilience can raise landed costs slightly, it often preserves revenue by maintaining on-time delivery and reducing stockouts, penalty fees, and emergency expedited freight.

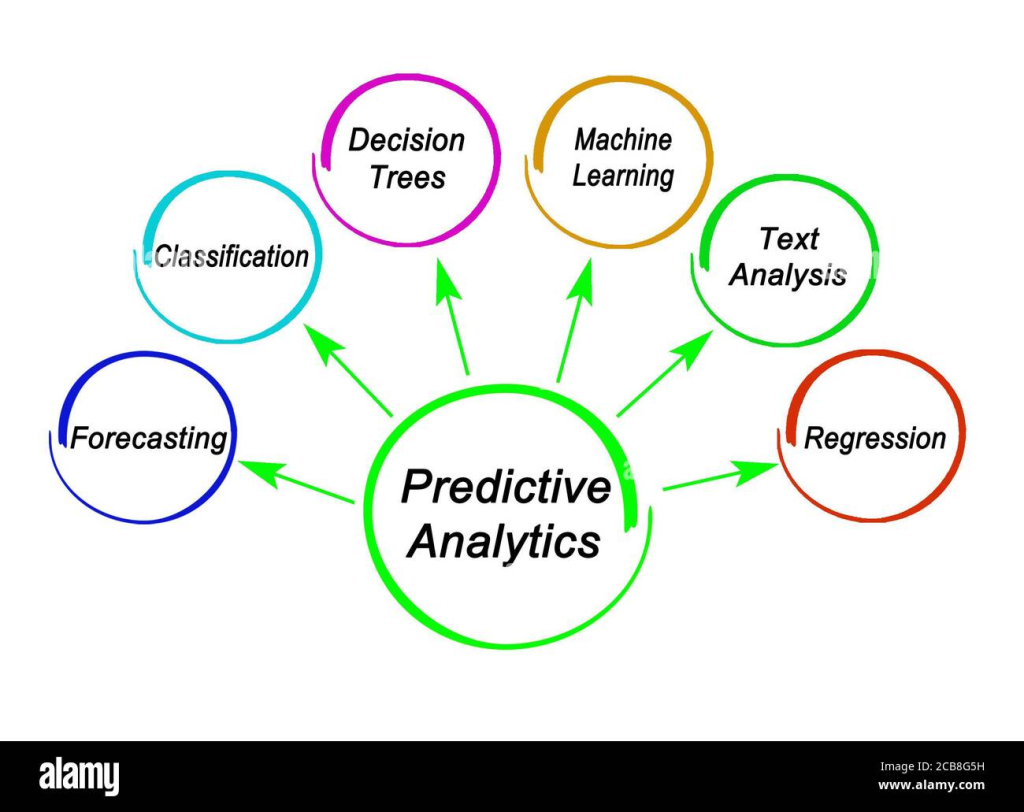

Effective strategic responses also require embracing digital tools and proactive procurement practices. AI-driven demand forecasting, scenario planning, and supplier risk scoring reduce uncertainty and support smarter decisions about sourcing, inventory levels, and contract terms. By aligning pricing with cost dynamics and preparing for tariff or policy shifts, firms can manage the wallet impact more predictably—trading volatility for steadier margins and sustained customer satisfaction.

Frequently Asked Questions

How do global trade trends and tariffs and trade policies influence supply chain resilience and shipping costs within Global Trade and Supply Chains?

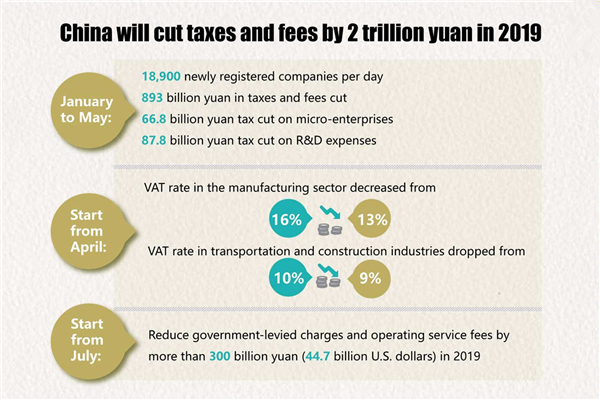

Global trade trends drive supplier diversification and nearshoring, boosting resilience by reducing exposure to single disruptions. Tariffs and trade policies raise input costs and can shift sourcing, altering landed costs and shipping costs. To protect margins, model policy scenarios, diversify suppliers, optimize inventory, and improve end-to-end visibility to respond quickly.

What strategies can businesses implement in Global Trade and Supply Chains to mitigate logistics disruption and manage shipping costs and freight rates?

Key strategies include strengthening supply chain visibility, diversifying suppliers with total landed cost analysis, and negotiating favorable freight terms. Use digital tools for AI forecasting and risk scoring, optimize routes and container usage, and consider multi-modal transport. Lock in rates with multi-year contracts and maintain strategic safety stock to weather disruption.

| Topic | Key Points | Wallet Impact & Strategic Takeaways |

|---|---|---|

| Global Context | Global Trade and Supply Chains are dynamic networks that respond to policy shifts, currency movements, energy prices, and seasonal demand. Wallet implications span procurement, manufacturing, inventory, and delivery, shaping pricing power and profitability. | Monitor global trends, hedge costs where possible, diversify suppliers, manage total landed cost, and align procurement with anticipated shifts to preserve margins and growth. |

| Global Trade Trends and Budgetary Implications | Trends include supplier diversification, regionalization (nearshoring/friend-shoring), and digital visibility. Diversification reduces disruption risk but can increase logistics complexity and unit costs; nearshoring shortens lead times. | Balance risk reduction with incremental expenses; adjust procurement and pricing to reflect landed costs; manage total cost of ownership across regions. |

| Supply Chain Resilience as a Margin Strategy | Resilience entails redundant suppliers, geographically distributed networks, inventory buffers, and real-time data visibility. It stabilizes service levels during disruptions. | Slightly higher landed costs can be offset by lower risk premiums, improved customer satisfaction, and fewer penalties; quantify ROI of resilience to justify investments. |

| Logistics Disruption and Real Costs | Congested ports, container shortages, rail bottlenecks, and trucking delays raise lead times and transportation costs. Freight rates surge; carriers favor higher-margin routes. | Implement container optimization, alternate transport modes, smarter routing; renegotiate terms with freight forwarders; strategic procurement to damp peak-season spikes. |

| Tariffs and Trade Policies | Policy changes alter input costs and finished-goods pricing, influencing domestic vs. foreign sourcing decisions. Firms may accelerate or delay purchases and adjust product design. | Model tariff scenarios, align procurement planning, maintain compliance and quality, and adapt sourcing strategies to shifts in policy. |

| Shipping Costs, Freight Rates, and Inventory Strategy | Shipping costs affect pricing and margins; stable freight costs boost competitiveness. Hedging through optimal inventory, multi-year contracts, and freight consolidation helps. | Balance demand forecasts with production schedules, optimize inventory, and pursue long-term contracts to stabilize cash flow and margins. |

| Strategic Responses for Businesses | Levers include: (1) enhanced visibility; (2) diversified suppliers with cost-awareness; (3) digital forecasting and risk scoring; (4) favorable terms negotiations; (5) pricing aligned with costs; (6) tariff preparedness. | Use visibility and data to reduce uncertainty; control total landed costs; insulate margins through dynamic pricing and flexible procurement terms. |

| Sectoral Impacts and Practical Examples | Sectors experience wallet impacts differently: electronics face component shortages and delays; consumer goods bear higher landed costs from port congestion; automotive relies on multi-tier networks; healthcare emphasizes timely access. | Improve cross-sector visibility, re-optimize supplier networks, and align pricing to sector-specific risks to outperform during volatility. |

| The Human Element: Leadership and Organizational Readiness | Leadership must set risk tolerance, priorities, and contingency plans. Cross-functional collaboration across procurement, logistics, finance, and product is essential. | Invest in training, scenario planning, and governance to stay prepared for shocks (tariffs, port delays, supplier stress). |

| Looking Ahead: What to Watch | Key trends include resilience/diversification, digital tools and risk scoring, dynamic pricing, regional production clusters, and evolving policy/regional trade agreements. | Prepare for continued shifts by monitoring indicators and updating strategies to maintain service levels and margins. |

Summary

Global Trade and Supply Chains remain a critical driver of business performance and consumer experience. The wallet-impact is driven by a confluence of global trade trends, supply chain resilience, logistics disruption, tariffs and trade policies, and fluctuations in shipping costs and freight rates. Companies that invest in visibility, diversify thoughtfully, and align procurement with robust scenario planning can navigate this complex landscape more effectively, protecting margins while continuing to meet customer expectations. By embracing data-driven decision-making and cross-functional collaboration, businesses can not only withstand shocks but also seize opportunities in a world where Global Trade and Supply Chains continually evolve. In this environment, staying informed about the latest developments in Global Trade and Supply Chains is not optional—it is essential for sustained growth and financial success.