Global supply chain news is not merely headlines; it functions as a compass guiding leaders through risk mapping, strategic procurement, and growth planning in an increasingly interconnected, uncertain world, providing a framework for measuring exposure, resilience, and opportunity in real time. As port lanes adjust and policy shifts ripple through factories, supply chain disruption becomes a daily reality that touches schedules, inventories, and customer expectations. Businesses are turning to logistics optimization—streamlined routing, smarter carrier selection, and precise inventory placement—to reduce latency and costs while maintaining service levels, sustainability considerations, and supplier collaborations that strengthen resilience across the network. Understanding broader market shifts helps firms anticipate tariff moves, currency swings, and supplier choices that shape long-term competitiveness. This article translates current developments into actionable strategies your team can implement today, helping executives turn risk into opportunity and guiding investment, procurement, and operations toward greater agility.

From a Latent Semantic Indexing perspective, the topic can be reframed as a reconfiguration of global sourcing, logistics networks, and production planning. In practice, executives describe it as a shift toward more resilient supplier bases, diversified sourcing, nearshoring where feasible, and investments in real-time visibility and data-driven decision making. The language emphasizes risk management, capacity planning, and end-to-end transparency as the core levers for maintaining service levels in volatile markets. By mapping these alternative terms to your existing operations, you can identify concrete steps to strengthen your value chain and sustain competitive performance.

Global supply chain news and resilience: turning disruption into competitive advantage

Global supply chain news underscores more than headlines; it maps the rhythms of risk and opportunity across industries. By tracking port congestion, container rates, labor shortages, and policy shifts, leaders can translate news into a practical risk map for procurement and production planning. When supply chain disruption tightens, logistics optimization becomes the operational backbone that preserves on-time delivery and customer satisfaction. Treated as a continuous signal, global supply chain news informs where to tighten buffers, where to move capacity, and how to reallocate capital to keep products flowing.

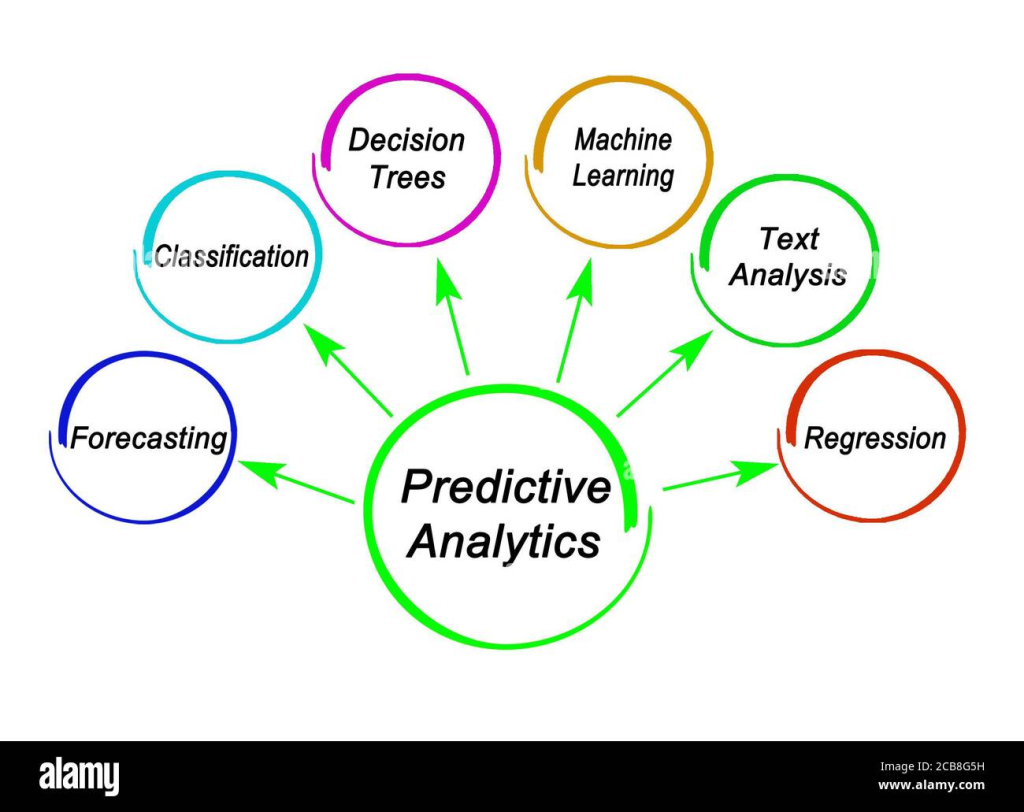

To turn insights into action, companies should diversify suppliers, build flexible contracts, and invest in end-to-end visibility. Real-time analytics, scenario planning, and proactive rerouting help anticipate shortages and maintain service levels even as volatility shifts. By embedding external signals—demand swings, geopolitical developments, tariff announcements—into replenishment and manufacturing plans, firms strengthen supplier resilience and reduce the risk of cascading delays in the network.

Leveraging global trade trends for supplier resilience and logistics optimization

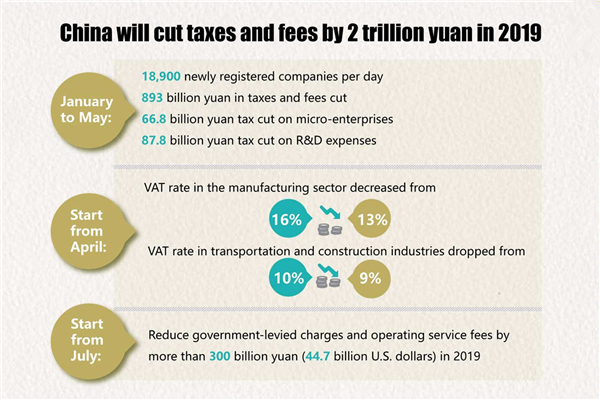

Global trade trends are a compass for sourcing and network design. Analyzing tariff changes, currency movements, and regulatory directions helps sourcing teams select regions with more predictable lead times and lower landed costs. Nearshoring and supplier diversification emerge as practical responses to risk, enabling tighter control over critical components while keeping logistics optimization front and center in distribution and transport planning.

Operational steps include building multi-sourced portfolios, negotiating value-based contracts, and deploying digital visibility platforms that track shipments across suppliers and carriers. Advanced analytics, predictive forecasting, and Monte Carlo risk modeling translate trade policy uncertainty into quantified scenarios, informing capital allocation and inventory strategies. The outcome is a more resilient, flexible network that adapts quickly to policy shifts and evolving demand, safeguarding margins and customer commitments.

Frequently Asked Questions

How can organizations act on global supply chain news to strengthen supplier resilience?

Treat global supply chain news as a trigger for action: diversify suppliers to build supplier resilience, secure multiple sourcing options, and establish contingency terms to weather shocks. Monitor port congestion and freight rates, invest in end-to-end visibility (IoT, RFID, and analytics), and run regular scenario planning to limit disruption impact while preserving service levels.

What strategies from current global trade trends help optimize logistics amid ongoing supply chain disruption?

Leverage nearshoring and supplier diversification to shorten lead times and reduce risk, while optimizing logistics through data-driven routing, carrier mix, and mode selection. Improve visibility with digital forecasting and scenario planning to anticipate supply chain disruption, and align procurement with trade policy changes to sustain cost efficiency and customer service.

| Aspect | Key Points |

|---|---|

| Driving forces | Aftershocks of the pandemic; demand volatility; geopolitical events and tariff changes; ocean freight volatility; technology acceleration with more visibility tools, data analytics, and automation. |

| Why it matters | Shifts affect margins, delivery reliability, and customer expectations. Requires rethinking supplier networks, improving inventory management, and embracing smarter logistics to act with agility, resilience, and foresight. |

| Key trends | 1) Resilience as a standard; 2) Nearshoring and supplier diversification; 3) Digitalization and visibility; 4) Data-driven risk management; 5) Sustainability and regulatory integration. |

| Industry implications | Retailers: inventory balance challenges; Manufacturers: sourcing continuity; Tech/electronics: value chain complexity; Food/CPG: cold chain; Across sectors: need for visibility, speed, and adaptability. |

| Practical strategies | Diversify suppliers and practice collaborative performance management; optimize logistics; invest in visibility tech; expand scenario planning; align procurement with global trade trends; foster continuous improvement. |

| What to monitor (12 months) | Freight rates and port congestion; tariff developments and new trade regulations; execution reliability of multi-source strategies; pace of digital adoption; sustainability benchmarks and supplier compliance. |